The difference between an explosion proof camera with a 316L stainless steel housing and one with 304

Huan He

July 25, 2024

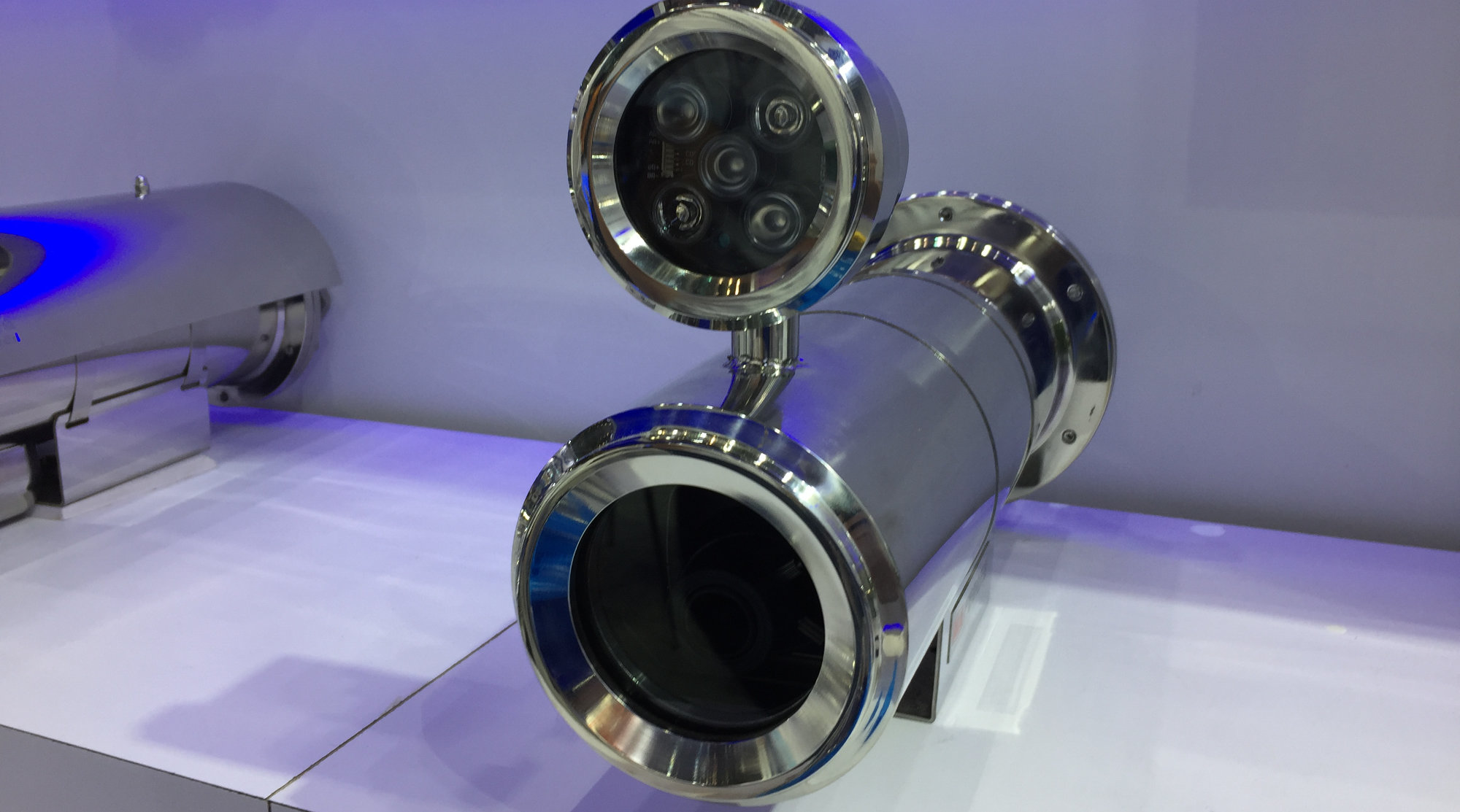

The main difference between an explosion proof cameras with a 316L stainless steel housing and one with a 304 stainless steel housing is the material composition, which affects the camera's resistance to corrosion and environmental conditions.

-

Explosion proof camera housing with 304 Stainless Steel

Composition: Contains approximately 18-20% chromium and 8-10.5% nickel, with a maximum of 0.08% carbon. Corrosion resistance: Provides good corrosion resistance, particularly in environments without chloride exposure. It is generally sufficient for most general purpose applications. Cost: Typically less expensive than 316L stainless steel due to the lower nickel and molybdenum content. Applications: Suitable for environments where the risk of corrosion is reduced, such as indoor or mild outdoor environments. -

Explosion proof camera housing with 316L Stainless Steel

Composition: Contains 16-18% chromium, 10-14% nickel, 2-3% molybdenum, and a maximum of 0.03% carbon. The addition of molybdenum provides enhanced corrosion resistance. Corrosion resistance: Superior to 304 stainless steel, especially in harsh environments with high exposure to chlorides (salt water) or other corrosive chemicals. The "L" in 316L stands for low carbon, which minimises carbide precipitation during welding and maintains corrosion resistance. Cost: More expensive than 304 stainless due to higher nickel and molybdenum content. Applications: Ideal for marine environments, chemical processing, or any application where exposure to corrosive elements is a concern. -

Summary

304 stainless steel: Cost effective, good corrosion resistance, suitable for general purpose use.

316L Stainless Steel:Higher cost, superior corrosion resistance, ideal for harsh environments.

The choice between the two depends on the specific environmental conditions and the required durability of the explosion proof camera. For environments with high corrosion potential, 316L stainless steel is the better choice.